6. Bhodhi rinozungunuswa otomatiki, uye hupamhi hwetini furnace wave peak inogona kugadziridzwa kuderedza huwandu hwetini oxidation.

7. 1800mm yakawedzera rudzi rwechitatu (china) nhanho preheating, infrared (mhepo inopisa) yakazvimirira PID tembiricha kutonga, Kunyangwe kudziyisa, yakachengeteka uye yakagadzikana.

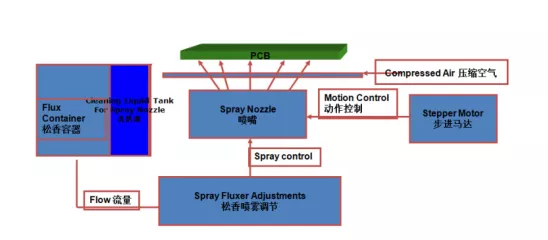

◆ NeLumina (Japan) nozzle, iyo spray range i20-65mm, kureba kwemuromo ndeye 50-80mm, uye iyo yakawanda inoyerera inosvika 60ml / min.

◆ Inoshandisa AirTAC (Taiwan) sefa, pointer gauge inoratidza kumanikidzwa kwemhepo, yese spray system mapaipi ari acid uye alkali inodzivirira corrosion protection pipes.

◆ Spraying system inotora scanning spraying method, muganhu wekuchinja uye maziso ekupinda anosanganiswa kuti adzore, uye PCB inongoonekwa ne inductive spraying maererano nekumhanya uye hupamhi hwePCB, kuitira kuti kunyorova kwehuwandu hwekuyerera kunogona kuita zvakanakisisa.Inlet spray musoro uye nhanho mota inoshanda, yakagadzikana uye yakavimbika.

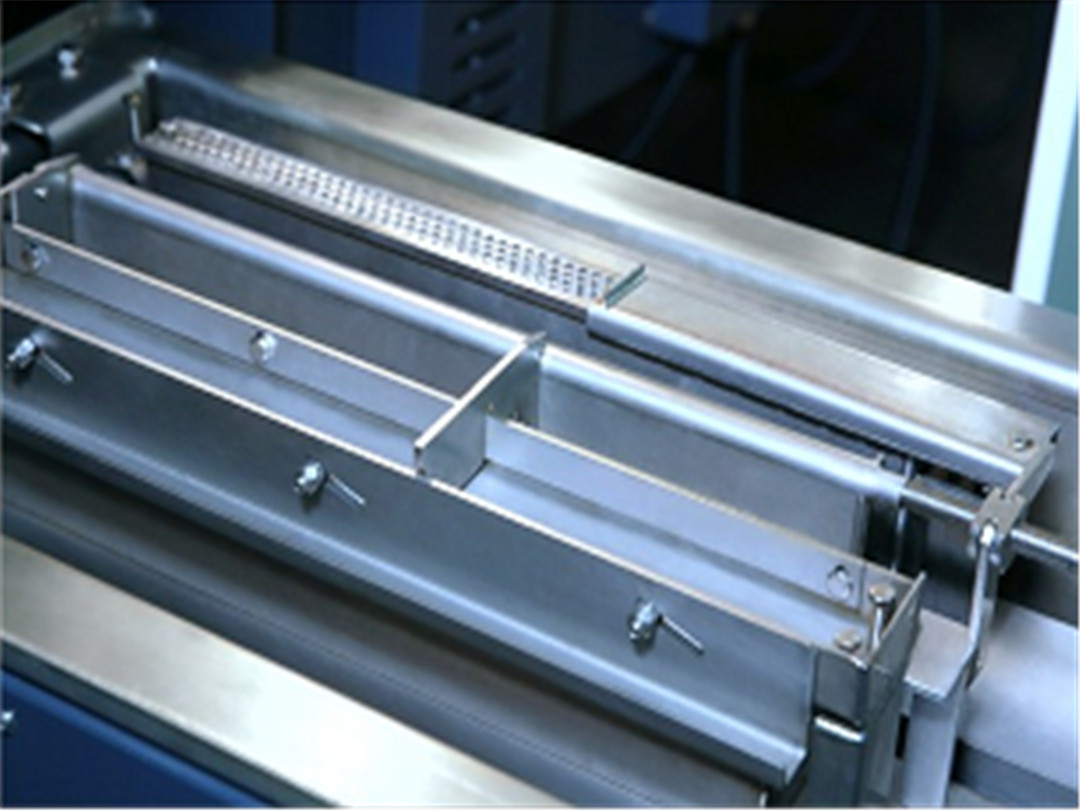

◆ Stainless steel bent forming tray inoshandiswa pasi pemusoro wekupfapfaidza pakutakura mvura yakasviba uye inoyerera, iyo inogona kutorwa nekucheneswa paunoda.

◆ The air extraction system is superimposed automatic recovery system ine mitsara mitatu yestainless steel wire mesh filtration kuderedza kusara kweflux blockage mumhepo inotorwa pombi kuburikidza nekushandisa maitiro emvura kusefa yakawandisa flux.

◆ Pneumatic air knife, iyo inoputira yakawandisa flux panguva yekupfapfaidza mutangi rekudzoreredza kudzivirira kubuda kwemvura kupinda munzvimbo yekupisa uye kuve nechokwadi chekuchengetedzwa kwekugadzira.

◆ Yese simbi isina tsvina + aluminium alloy support, nyore kuchenesa nekugadzirisa, yakasimba corrosion resistance, yakasimba.

Welding System

1. 4mm SUS316L Inotengeswa kunze kwesimbi isina tsvina yevira, dhizaini nyowani yechoto liner, yakanaka kutaridzika, iri nyore kuchenesa, yakakandwa simbi inopisa ndiro, choto liner haina kuremara.

2. Disturbance wave crest, guided jet, the best soldering of SMD components, the wave crest inotsvedzerera segirazi.

3. Hupamhi hwepeak wave inochinjika kuderedza huwandu hwetin oxidation, uye sefa inogona kuburitswa kunze pasina kuparadzanisa muromo.

4. Wedzera chivharo che-anti-oxidation panzvimbo ye impeller shaft kuderedza kuwanda kwetini oxidation inokonzerwa nekutenderera kwe impeller shaft.

5. Iyo impeller shaft uye wave mota inogona kupatsanurwa zvakasiyana pasina kupatsanura tin chiteshi (mamwe mabhureki ewave soldering haagone kuita dhizaini iyi)

Transport System

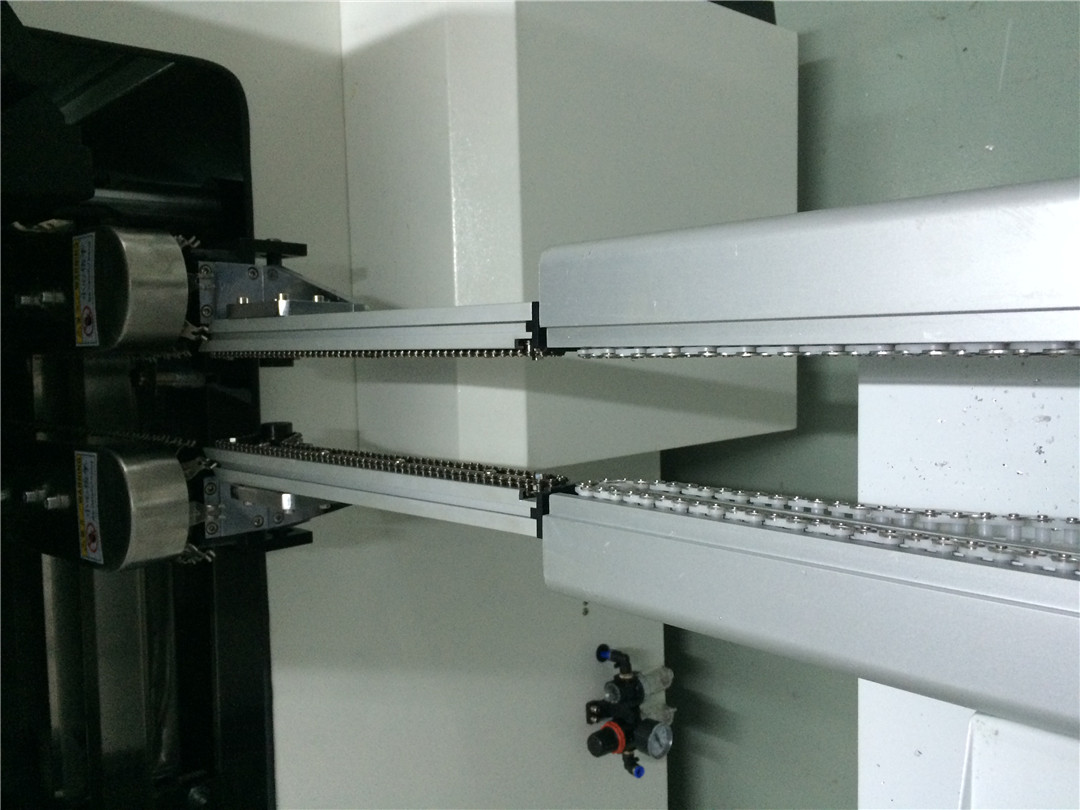

Yakachena aluminium zvinhu otomatiki yekudyisa uye yekubatanidza mudziyo, yakatsetseka uye yakagadzikana yekudyisa, kugadzirisa kukuru

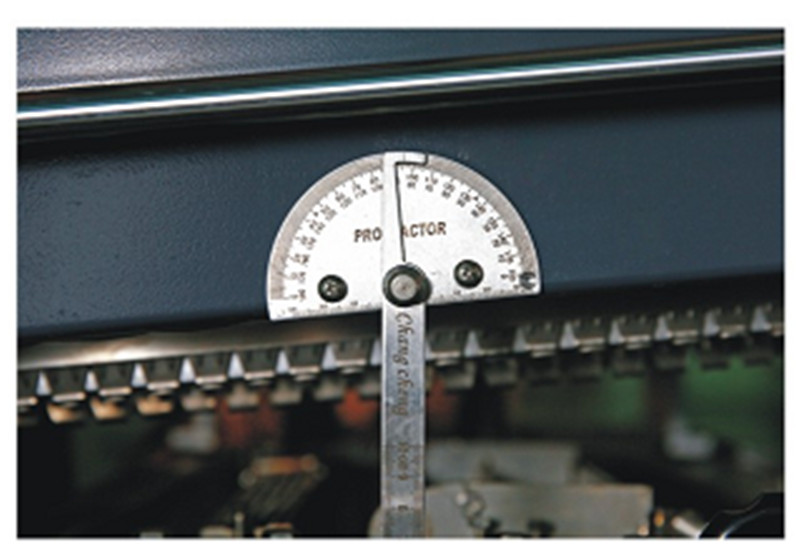

Iyo njanji ine yayo tilt angle mudziyo, iyo inogona kunyatso tarisisa kona yekutenderera uye kutonga kunaka kwebhodhi.

Titanium alloy claw hooks inovimbisa kuti tini harizombosvibiswa, uye nhanho nhatu dzakagadzika njanji dzinoona kuti njanji haizombotsva, izvo zvinodzivirira zvinodzivirira njanji kuti dzisadonha uye kudhumhana.

◆Iyo 4mm copper bead inoita kuti kutakurwa kuite mutserendende uye kugadzikana.(Mazhinji mamwe mabhureki anoshandisa Stainless simbi layering, isingagone kuvimbisa kufambisa kwakatsetseka kwenguva yakareba.)

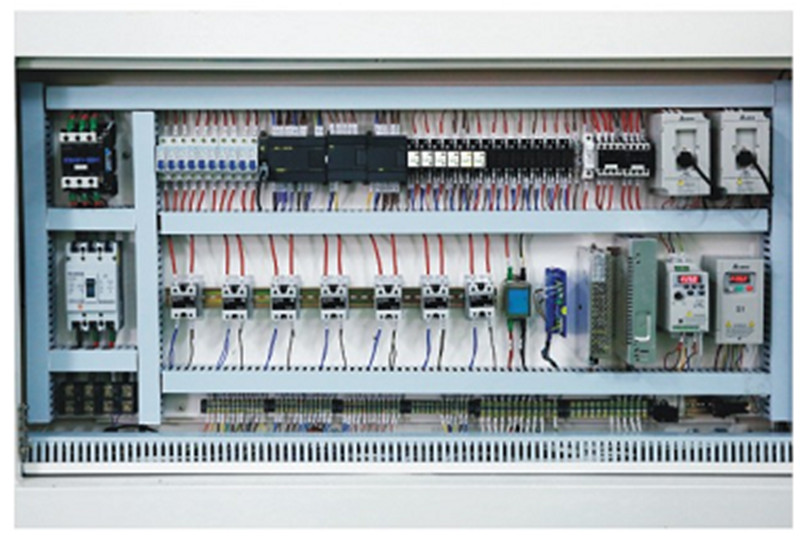

Iyo yakareruka inoshanda sisitimu yakanakira vashandi kuti vashande, uye iyo PC + PLC yekudzora sisitimu inoita kuti tembiricha yekudzora iko kurongeka uye kugadzikana.

Zvigadzirwa zvemagetsi zvese zvinozivikanwa mabhureki kumba nekune dzimwe nyika, uye yekutanga Siemens PLC inovimbisa kuti sisitimu yakachengeteka uye yakagadzikana.

Kudzora tembiricha kunotora yega-tuning PID control algorithm, hapana chikonzero chekuisa nemaoko PID paramita, yakakwirira kutonga kurongeka.

Technical parameters

| Model | CY-350B/T | CY-450B/T |

| Nhamba yenzvimbo yekudziya | Kutsika mota kana silinda isina tsvimbo | |

| Nhamba yenzvimbo yekutonhora | 6 LITERS | |

| Air pressure yekuyerera | 3-5BAR | |

| Preheating Mode | Mhepo inopisa / infrared | |

| Preheating Zone Number | 4 chikamu | |

| Preheating Length | 1800mm | |

| Nguva yekudziya | Approx.15min | |

| PCB hupamhi hwepamusoro | 350mm | 450mm |

| Tungamira huwandu hwakawanda | 50-350mm | 50-450mm |

| Conveyor Speed | 0-2000mm/min | |

| Conveyor Height | 750±20mm | |

| Nzira yekufambisa | L→R (R→L) | |

| Transmission nzira | 4-7° | |

| Solder tembiricha | 9KW (Tembiricha yemumba-300℃) | |

| Solder capacity | 400Kg | 500Kg |

| Kudzora nzira | Brand Computer (Windowsoperating system)+Siemens PLC | |

| Conveyor speed | 3∮ AC380V 90W,Chiratidzo: Tai Chuang | |

| Wave mota | 3∮ AC220V 360W*2pcs,Chiratidzo: Tai Chuang | |

| Pombi yekuchenesa zvigunwe | 1P AC220V 10W | |

| Zvigunwe | Special titanium alloy double groove claw | |

| Kutonhodza system | Kutonhodzwa kwemhepo | |

| The power supply | 5-waya 3-chikamu 380V 50/60Hz | |

| Tanga simba | 38Kw | |

| Normal kushanda simba | Approx10Kw | |

| Temperature control mode | Yakazara komputa PID yakavharwa loop control, SSR drive | |

| Aramu isina kujairika | Tembiricha isina kujairika (yakanyanya kukwirira kana kuderera zvakanyanya mushure mekupisa nguva dzose) | |

| Chiedza chemavara matatu | Chiedza chemavara matatu-mavara: yellow-heating;green-inogara tembiricha;dzvuku-zvisina kujairika | |

| Kurema | Approx.1800Kg | Approx.2000Kg |

| Installationdimension (mm) | L4300×W1530×H1700mm | |

| Exhaust mweya zvinodiwa | 10 cube / min 2 nzira∮200mm | |