Reflow soldering inhanho yakakosha mukuita kweSMT.Iyo tembiricha mbiri yakabatana nereflow ndiyo yakakosha parameter yekudzora kuti ive nechokwadi chekubatana kwezvikamu.Iwo maparamendi ezvimwe zvikamu achakanganisawo zvakananga tembiricha yakasarudzwa kune iyo nhanho mukuita.

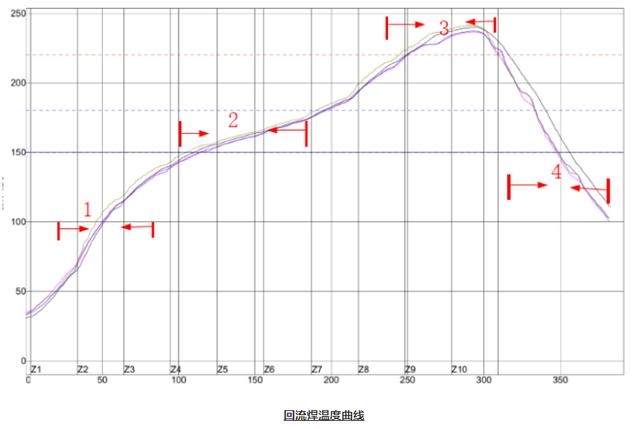

Pane maviri-track conveyor, mabhodhi ane zvichangobva kuiswa zvikamu anopfuura nepakati penzvimbo dzinopisa uye dzinotonhora dzehovhoni yekuyerera.Aya matanho akagadzirirwa kunyatso kudzora kunyunguduka uye kutonhora kweiyo solder kuzadza majoini e solder.Iko shanduko huru yetembiricha ine chekuita neiyo reflow profil inogona kukamurwa kuita zvikamu zvina / matunhu (akanyorwa pazasi uye anoratidzwa pano):

1. Kudziya

2. Kugara kuchipisa

3. Kupisa kwepamusoro

4. Kutonhodza

1. Preheating zone

Chinangwa cheiyo preheat zone ndeye kushandura yakaderera melting point solvents mune solder paste.Izvo zvikamu zvikuru zve flux mu solder paste zvinosanganisira resins, activators, viscosity modifiers uye solvents.Basa re solvent rinonyanya semutakuri we resin, nebasa rekuwedzera rekuchengetedza zvakakwana kuchengetwa kwe solder paste.Iyo preheating zone inoda kutenderedza solvent, asi tembiricha inokwira inokwira inofanirwa kudzorwa.Kuwedzera kupisa mitengo kunogona kushungurudza chikamu, icho chinogona kukuvadza chikamu kana kuderedza kuita kwayo / hupenyu hwese.Imwe divi mhedzisiro yekunyanya kupisa mwero ndeyekuti solder paste inogona kudonha uye kukonzera mapfupi maseketi.Izvi ndezvechokwadi kunyanya kune solder pastes ine high flux content.

2. Constant tembiricha zone

Kumisikidzwa kwenzvimbo yekushisa inogara kuchinyanya kudzorwa mukati mezviyero zvemutengesi paste wekutengesa uye huwandu hwekupisa hwePCB.Danho iri rine mabasa maviri.Yekutanga ndeyekuzadzisa tembiricha yakafanana yePCB board yese.Izvi zvinobatsira kudzikisira mhedzisiro yekushushikana kwekupisa munzvimbo yekuyerera uye kudzikamisa zvimwe zvirema zvekutengesa senge hombe vhoriyamu chikamu chekusimudzira.Imwe mhedzisiro yakakosha yeiyi nhanho ndeyokuti iyo inoyerera mune solder paste inotanga kuita zvehasha, ichiwedzera kunyorova (uye pamusoro pesimba) reiyo weldment pamusoro.Izvi zvinova nechokwadi chekuti solder yakanyungudutswa inonyorovesa nzvimbo yekunyungudutsa zvakanaka.Nekuda kwekukosha kwechikamu ichi chemaitiro, soak nguva uye tembiricha inofanirwa kudzorwa zvakanaka kuti ive nechokwadi chekuti iyo flux inochenesa zvachose nzvimbo dzekutengesa uye kuti iyo inoyerera haina kupedzwa zvachose isati yasvika kune reflow soldering process.Izvo zvinodikanwa kuchengetedza iyo flux panguva yekuyerera kwechikamu sezvo ichifambisa iyo solder wetting process uye inodzivirira re-oxidation yeiyo soldered surface.

3. Nzvimbo yekushisa yepamusoro:

Iyo yakanyanya tembiricha nzvimbo ndipo panoitika kunyungudika nekunyorova kwakazara uko iyo intermetallic layer inotanga kuumbwa.Mushure mokusvika pakupisa kwepamusoro (pamusoro pe217 ° C), kutonhora kunotanga kudonha uye kuwira pasi pemutsara wekudzoka, mushure mokunge solder inosimbisa.Ichi chikamu chemaitiro chinodawo kunyatsodzorwa kuitira kuti tembiricha inokwira kumusoro uye pasi ramps irege kuisa chikamu pakuvhunduka kwekupisa.Iyo yakanyanya tembiricha munzvimbo inoyerera inotarwa nekupikiswa kwekushisa kwekushisa-sensitive zvikamu paPCB.Iyo nguva iri munzvimbo yepamusoro yekupisa inofanirwa kuve ipfupi sezvinobvira kuti ive nechokwadi chekuti zvikamu zvinodziya zvakanaka, asi kwete kureba zvekuti iyo intermetallic layer inova gobvu.Nguva yakakodzera munharaunda iyi kazhinji 30-60 masekondi.

4. Nzvimbo yekutonhodza:

Sechikamu chezvese reflow soldering process, kukosha kwenzvimbo dzekutonhora kunowanzo furatirwa.Iyo yakanaka yekutonhora maitiro inoitawo basa rakakosha mukupedzisira mhedzisiro ye weld.A good solder joint inofanira kuva yakajeka uye yakapfava.Kana iyo yekutonhodza mhedzisiro isiri yakanaka, matambudziko mazhinji anoitika, senge kukwidziridzwa kwechikamu, majoini akasvibira, majoini asina kuenzana uye kukora kweiyo intermetallic compound layer.Naizvozvo, reflow soldering inofanirwa kupa yakanaka kutonhora mbiri, isingaite zvekumhanya kana kunonoka.Kunyanya kunonoka uye iwe unowana zvimwe zvambotaurwa zvisina kunaka kutonhora nyaya.Kutonhodza nekukurumidza kunogona kukonzera kupisa kunotyisa kune zvikamu.

Pakazara, kukosha kweiyo SMT reflow nhanho haigone kuderedzwa.Nzira yacho inofanira kutungamirirwa zvakanaka kuti zvive nemigumisiro yakanaka.

Nguva yekutumira: May-30-2023