Reflow soldering (reflow soldering / oven) ndiyo inonyanya kushandiswa pamusoro pechikamu chesolder nzira muSMT indasitiri, uye imwe nzira yekushongedza ndeye wave soldering (Wave soldering).Reflow soldering inokodzera zvikamu zveSMD, nepo wave soldering yakakodzera Yepini yemagetsi zvikamu.Nguva inotevera ndichataura zvakananga nezve musiyano pakati pezviviri.

Reflow Soldering

Wave Soldering

Reflow soldering zvakare iri reflow soldering maitiro.Nheyo yayo ndeyekudhinda kana kupinza huwandu hwakakodzera hwesolder paste (Solder paste) paPCB padhi uye kumisa inoenderana SMT chip kugadzirisa zvikamu, uye wozoshandisa inopisa air convection heat ye oven reflow kupisa tini Iyo paste inonyunguduka. uye yakaumbwa, uye pakupedzisira inovimbika solder joint inoumbwa nekutonhodza, uye chikamu chakabatana nePCB pad, iyo inotamba basa rekubatanidza magetsi uye magetsi.Iyo reflow soldering process yakaoma uye inosanganisira ruzivo rwakasiyana.Iyo ndeye tekinoroji nyowani interdisciplinary.Kazhinji kutaura, reflow soldering yakakamurwa kuita nhanho ina: preheating, tembiricha isingaperi, kuyerera, uye kutonhora.

1. Preheating zone

Preheating zone: Ndiyo yekutanga kupisa nhanho yechigadzirwa.Chinangwa chayo ndechekupisa chigadzirwa nekukurumidza pakupisa kwekamuri uye kumisa solder paste flux.Izvo zvakare kudzivirira kupisa kwechikamu kunokonzerwa nekukurumidza-yepamusoro-tembiricha kupisa panguva inotevera yekunyudza tin.Nzira yekupisa inofanirwa kukanganisa.Nokudaro, chiyero chekupisa chinonyanya kukosha kune chigadzirwa, uye chinofanira kudzorwa mukati mehutano hwakanaka.Kana ikanyanya kukurumidza, kuvhunduka kwekushisa kuchaitika, uye bhodhi rePCB uye zvikamu zvichaiswa pasi pekunetseka kwekupisa, zvichikonzera kukuvara.Panguva imwecheteyo, iyo inonyungudutsa mune solder paste inoputika nekukurumidza nekuda kwekupisa nekukurumidza.Kana ikanyanya kunonoka, solder paste solvent haizokwanisi kunyungudika zvizere, izvo zvinokanganisa kunaka kwekutengesa.

2. Constant tembiricha zone

Constant tembiricha zone: chinangwa chayo ndechekudzikamisa tembiricha yechimwe nechimwe chikamu paPCB uye kusvika pakubvumirana zvakanyanya sezvinobvira kuderedza kupisa kwekushisa pakati pezvikamu.Panguva ino, nguva yekupisa yechikamu chimwe nechimwe inenge yakareba.Chikonzero ndechekuti zvidimbu zvidiki zvinotanga kusvika pakuenzanisa nekuda kwekupisa kushoma kunyura, uye zvikamu zvakakura zvinoda nguva yakakwana yekubata nezvikamu zvidiki nekuda kwekupisa kukuru.Uye ive shuwa kuti flux mu solder paste yakanyungudika zvizere.Panguva ino, pasi pekuita kwekuyerera, maokisidhi pamapadhi, mabhora ekutengesa uye mapini echikamu achabviswa.Panguva imwecheteyo, flux inobvisawo mafuta pamusoro pezvikamu uye mapadhi, kuwedzera nzvimbo ye soldering, uye kudzivirira zvikamu kubva pakusvibiswa zvakare.Mushure mekunge nhanho iyi yapera, chikamu chega chega chinofanirwa kuchengetwa chakafanana kana tembiricha yakafanana, zvikasadaro panogona kunge paine kushomeka kwekutengesa nekuda kwekunyanya kupisa mutsauko.

Iyo tembiricha uye nguva yekushisa inogara ichienderana nekuoma kwePCB dhizaini, mutsauko muzvikamu zvezvikamu uye huwandu hwezvikamu, kazhinji pakati pe120-170 ° C, kana PCB yakanyanya kuoma, tembiricha yenzvimbo yekushisa inogara ichipisa. inofanirwa kutemerwa nekunyorovesa tembiricha yerosin sereferensi, chinangwa ndechekudzikisa nguva yekutengesa munzvimbo yekumashure-yekupedzisira reflow zone, iyo inogara tembiricha nzvimbo yekambani yedu inowanzosarudzwa pa160 madhigirii.

3. Reflow zone

Chinangwa che reflow zone ndechekuita kuti solder paste isvike pakunyungudutswa uye kunyorovesa mapadhi pamusoro pezvinhu zvinotengeswa.

Kana PCB board ichipinda munzvimbo yekuyerera, tembiricha inokwira nekukurumidza kuita kuti solder paste isvike pakunyungudika.Iyo yakanyunguduka ye lead solder paste Sn: 63 / Pb: 37 i 183 ° C, uye inotungamira-isina solder paste Sn: 96.5 / Ag: 3 / Cu: Iyo yekunyungudika ye0.5 i217 ° C.Munharaunda iyi, kupisa kunopiwa nemudziyo ndiko kwakanyanya, uye kutonhora kwechoto kuchaiswa kune yakakwirira, kuitira kuti kutonhora kwe solder paste kukwire kusvika pakupisa kwepamusoro nokukurumidza.

Iyo tembiricha yepamusoro yereflow soldering curve inowanzo tsanangurwa nenzvimbo yekunyunguduka yesolder paste, PCB board, uye tembiricha inodzivirira kupisa kwechikamu chacho pachayo.Kupisa kwepamusoro kwechigadzirwa munzvimbo yekuyerera kunosiyana zvichienderana nerudzi rwesolder paste inoshandiswa.Kazhinji, hapana Tembiricha yepamusoro-soro yelead solder paste inowanzoita 230-250°C, uye iya ye lead solder paste inowanzoita 210-230°C.Kana tembiricha yepamusoro yakadzikira, zvinokonzeresa kutonhora kudziya uye kusakwana kunyorova kwemasolder joints;kana yakanyanya kukwirira, epoxy resin type substrates ichaita Uye chikamu chepurasitiki chinowanzoita coking, PCB inopupuma uye delamination, uye zvinozotungamira mukuumbwa kweakawandisa eutectic simbi makomisheni, zvichiita kuti majoini anotengeswa ave brittle, achinetesa simba rewelding, uye kukanganisa mashandiro emagetsi echigadzirwa.

Inofanira kusimbiswa kuti kuputika mumucheka we solder munzvimbo inoyerera kunobatsira kukurudzira kunyorova kwechigadziro che solder uye kuguma kwechikamu chechikamu panguva ino, uye kuderedza kushushikana kwepamusoro kweiyo solder paste.Nekudaro, nekuda kwekusara kweokisijeni uye simbi yepasi oxides muchoto chekuyerera, Kusimudzira kwekuyerera kunoita sechidziviriro.

Kazhinji tembiricha yechoto yakanaka inofanirwa kusangana nepamusoro tembiricha yepoindi yega yega paPCB kuti ienderane sezvinobvira, uye mutsauko haufanire kudarika 10 madhigirii.Nenzira iyi chete tinogona kuve nechokwadi chekuti zviito zvese zvekutengesa zvakapedzwa zvinobudirira kana chigadzirwa chapinda munzvimbo yekutonhora.

4. Kutonhora nzvimbo

Chinangwa chenzvimbo yekutonhora ndechekukurumidza kutonhorera yakanyungudutswa solder paste zvimedu, uye nekukurumidza kugadzira majoini akajeka ekutengesa ane inononoka arc uye yakazara tini zvirimo.Naizvozvo, mafekitori mazhinji achadzora nzvimbo yekutonhora, nekuti inokodzera kuumbwa kwemajoini e solder.Kazhinji, kukurumidza kutonhora kutonhora kuchaita kuti solder yakanyungudutswa inonoka kutonhora uye buffer, zvichikonzera kukwenya, kurodza uye kunyange maburrs pamajoini akagadzirwa.Kunyanya kutonhora kutonhora kuchaita kuti nzvimbo yekutanga yePCB pad pamusoro Zvishandiso zvinosanganiswa mune solder paste, izvo zvinoita kuti majoini anotengeswa ave akaomarara, asina chinhu uye akasviba solder majoini.Uyezve, ese simbi magazini pamusoro soldering migumo yezvikamu zvichanyunguduka ari soldering majoini, zvichiita soldering magumo ezvikamu kuramba wetting kana murombo soldering.Inokanganisa kunaka kwekutengesa, saka kutonhora kwakanaka kunokosha zvikuru kune solder joint formation.Kazhinji, vatengesi vepaste paste vanokurudzira chiyero chekutonhodza chejoint ye ≥3°C/S.

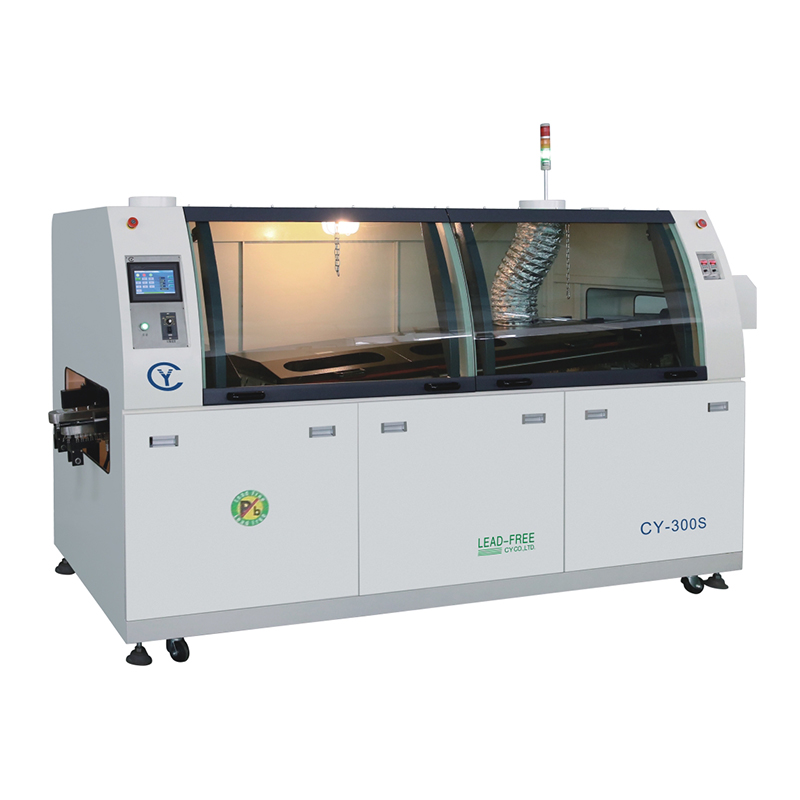

Chengyuan Indasitiri ikambani inoshanda mukupa SMT uye PCBA yekugadzira mutsara michina.Inokupa iwe mhinduro yakakodzera iwe.Iine makore akawanda ekugadzira uye ruzivo rwekutsvaga.Nyanzvi dzehunyanzvi dzinopa nhungamiro yekuisa uye mushure mekutengesa-musuo nesuo sevhisi, kuitira kuti usanetsekane.

Nguva yekutumira: Mar-06-2023